Explain the Different Approaches Towards Continuous Process Improvement

You may be familiar with Six Sigma Kaizen Lean Toyota Production System and others. Value stream mapping is one of the most important continuous improvement strategies because it can be used within almost all others.

Recognize or identify an opportunity and plan for a change.

. Continuous Improvement Tools and Techniques Kanban. The process mapping will show graphically the flows in the process from start to finish which will include activities personnel and the outcomes. Since continuous improvement drives long term change there are a series of steps required in the planning and implementation of a Continuous Improvement program.

1DMAIC Define - Identify the improvement opportunity Measure - Capture the process data for documentation Analyse - Find the root causes of the process problem focus on causes not symptoms Improve - Determine the steps that should be taken to improve the process Control - Monitor any change. Theyre for the type of improvements that you need expertise on and not something the average joe can just suggest. Among the most widely used tools for the continuous improvement model is a four-step quality assurance methodthe plan-do-check-act PDCA cycle.

The PDCA cycle short for plan do check act provides you with a systematic approach to testing different ideas and hypotheses. This is a four-step quality model that focuses on achieving continuous improvement by following four specified steps within a cycle. Implement the plan for change on a small scale.

It is about delivery of war-fighting capabilities today and tomorrow. This guide gives a quick overview of each of the process improvement techniques. Ben Mulholland Editor at Process Street defines continuous improvement as a method to make sure that your processes methods and practices are as efficient accurate and effective as possible.

The fundamental approach that serves as the basis for most process improvement models is known as the PDSA cycle which stands for Plan Do Study Act. Continuous improvement isnt about setting a high pace. Well do deep dives on each subsequently in this series.

The benefit that the process map gives to providing continuous improvement is that it defines the scope of the process the interface with other processes and a starting point from which improvement can be measured. To establish a culture of continuous improvement he recommends using 2 types of processes. Heres an overview of the six most popular and effective continuous improvement tools available.

The first step towards streamlining your work processes is identifying whats slowing them down. Above all to find out how to work better as a team. Plan Do.

The first is a team of experts specializing in process improvement through statistical tools and software. Many manufacturing companies have an established and proven process to handle job quotes and orders formalized training for new employees as well as metrics and. They consist of the following activities.

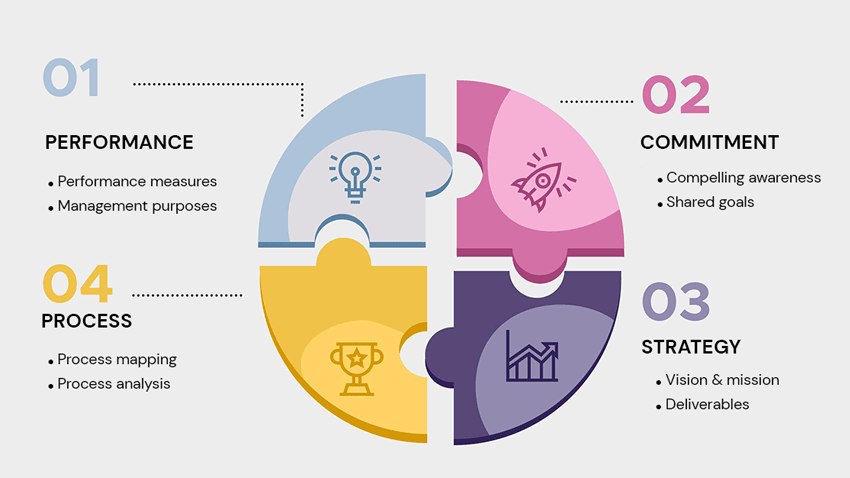

Use data to analyze the results of the change and determine whether it. Its about changing everyones mindset to a systematic way of finding better ways to do things. The Continuous Process Improvement Model.

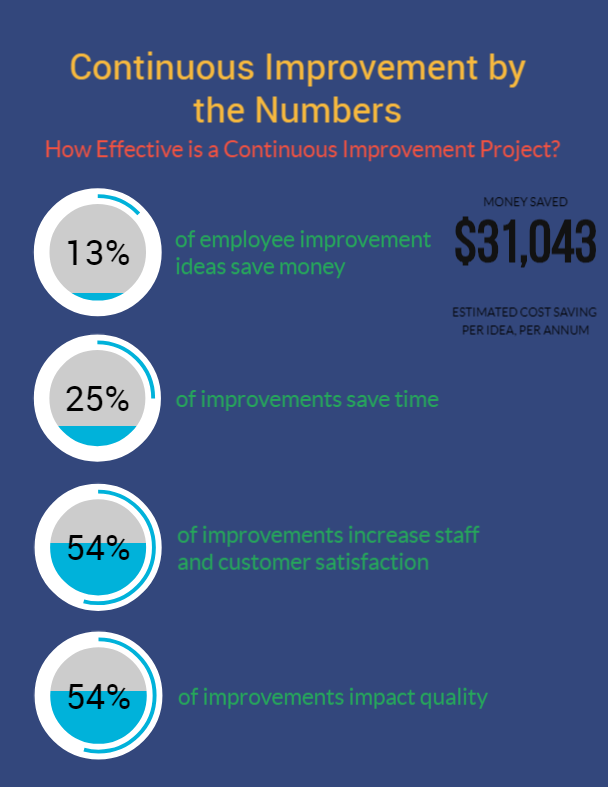

Improving business performance is closely related to the concepts of idea management and process improvement. This is done by periodically examining and improving your processes to smash bottlenecks use the best software and. Identify an opportunity and plan for change.

However Kaizen events can be applied in specific circumstances when quick fixes are needed as they require 2-5 days. Here are some considerations for how to make continuous process improvement the norm within your business. A3 is a structured approach to problem solving used by Lean and Agile organizations.

You can learn from your experiences and then use those lessons to shift strategy and try new interventions as needed so you continually move incrementally toward your improvement goals. Kanban helps you harness the power of visual information by using sticky notes on a whiteboard to create a. What is Continuous Improvement.

The term A3 describes a type of. The continuous improvement model reflects the idea that organizations should undertake incremental improvements to services products and processes. It recognizes the processes by which you build your product and your company as one of the key risk factors affecting success.

As mentioned above continuous process improvement doesnt always have a clear beginning and end. Yes the systematization of the Canvas Model has helped many companies create business plans in an agile and fast way. Value Stream Mapping.

Continuous Improvement Assessment will provide you with an understanding of the operating challenges a Continuous Improvement program will face. Continuous process improvement stops you from getting comfortable with the status quo and accepting sub par results. Instead it works best when it is part of the company culture and involves everyone within an organisation.

Its about finding a rhythm that works for your organization. This process looks at the design and flow of processes within a company to see where value is being added. CPI is a transformational initiative empowering all Airmen to eliminate waste from every end-to-end process.

The continuous improvement approach not only eliminates wasteful steps that add no value but also eliminates the quality problems that stem from this cost time and resource drain. But its important to. As illustrated in Figure 4-1 this.

A process improvement methodology born in Japan kaizen espouses the idea that business improvement is continuous and never ending. Although these methodologies differ the foundation of each of them is the continuous improvement model. CPI is an improvement process which leverages improvement methods from various sources including Lean Six Sigma Theory of Constraints and Business Process Reengineering.

Implement the change on a small scale. Here are 6 tips for implementing continuous process improvement. When one speaks of the lean approach to process improvement many immediately think of the Canvas Business Model also called the Canvas Model and associate the methodology with Alexander Osterwalder.

In contrast to the concept of innovation and the method of innovation management where progress is often achieved through technological leaps the continuous improvement process is a far more gradual method. There are many process improvement methodologies to identify bottlenecks and inefficiencies in your processes. It can help you to implement continuous improvement throughout your organization using a structured framework.

For sustaining improvement to occur CI processes have to be a long-term approach. A Kaizen event is a short-term approach as part of a continuous improvement process. Quality Teams and Kaizen Corners.

What Is Continuous Improvement A Simple Guide

What Is Continuous Process Improvement Cpi Cflow

Lean Enterprise Kore 10 Trainsitioning Tips Kaizen Practices 5 Approaches 5 Methods Continuous Improvement Lean Enterprise Process Improvement Kaizen

0 Response to "Explain the Different Approaches Towards Continuous Process Improvement"

Post a Comment